1. Fine grading the stone

(aggregate) base.

This base is naturally porous. Note the

white covered rolls of turf already on site. |

2. Shooting grade to assure

proper tolerance-to-grade for subbase. |

3. Testing the permeability. |

4. Final "proof role"

of subbase to get 95% compaction. |

5. Initial panel marked and

rolled out. |

6. Team of local workers help

roll out the product. |

7. Project Manager, Gary Baumer,

performs

key seam work and controls the installation quality. Note

that Gary wears a "yellow"

shirt - your guarantee of top quality, experience and

certification from AstroPlay. |

8. Lines are glued to a special

tape with high quality, two-component urethane. |

9. Lines are in. Time to start

filling the field

with rubber. |

10. Rubber granules are placed

on the field and then brushed into the fibers. |

11. Loading more rubber granules

in the

AstroPlay spreader. |

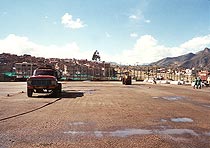

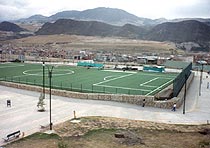

12. An oasis of green in a

desert plateau. |

13. The superintendent and our

Project

Manager - another job done on time. |

14. Because the community built

the field, the community is invited to inspect it. |

¡@